[ad_1]

Chocolate is just one of the world’s most popular flavours, potentially next only to vanilla. This tends to make cocoa powder a favoured ingredient in many foods products and solutions, such as UHT dairy and dairy choice beverages. Even though bacteria-relevant spoilage for these items is unusual, decreasing food stuff squander is a concern for each and every player in the food manufacturing chain.

René Floris, NIZO Food Research Division Supervisor and member of the FoodNavigator pro advisory panel, asks Robyn Eijlander, Microbiology and Food stuff Safety specialist at NIZO, about the problems, and how a consortium of cocoa suppliers, cocoa buyers and engineering companies is serving to get to the root of the make a difference, employing a holistic, science-dependent technique.

René Floris: What challenges do food providers facial area when working with cocoa powder?

Robyn Eijlander: Cocoa powder has a quantity of one of a kind features that can make it demanding to get the job done with. It is hydrophobic, so it does not completely hydrate when mixed with drinking water. You have to blend the powder with a tiny volume of liquid first to kind a slurry, then merge the slurry with the rest of the liquid. But there is even now a possibility that little lumps or voids will remain dry. Cocoa powder also consists of starch, so at pretty superior temperatures it can gel, which impacts hydration, as properly.

In addition, there is proof from food producers that bacterial spores in cocoa powder can once in a while trigger spoilage in UHT liquid items. This is an unforeseen and unpredictable final result, however, due to the fact cocoa powder commonly includes quite low concentrations of hugely warmth-resistant bacterial spores that could probably survive the thermal procedures. The unpredictability will make it hard for companies to evaluate the hazards, and optimise procedures.

To clear up this problem, we have to search at the microbiology, powder physiology and processing, which requires cooperation from the cocoa powder suppliers, approach technologies companies and cocoa buyers, i.e., the foods makers.

RF: How do the bacterial spores get into cocoa powder?

RE: Portion of the processing of cocoa beans is all-natural fermentation, which gives chocolate its lovely and perfectly-appreciated flavour. This fermentation will take area on-web-site at the smaller cocoa farms scattered throughout Africa, South America and Indonesia. The existence of bacterial spores is an unavoidable outcome of this system.

These bacterial spores are resistant to heat, acidification, and many others., so they may perhaps endure the cocoa powder production method, and even the UHT beverage manufacturing process. Then, less than the ‘right’ disorders, they can germinate and develop into metabolically lively once more, spoiling the item. The two most predominant spore-forming microbes observed in cocoa powder are Bacillus subtilis and Bacillus licheniformis, which are infamous for a huge strain-to-strain selection in spore warmth resistance. Simply identifying the species for that reason doesn’t forecast the risk of likely spoilage.

RF: How can the bacterial spores be inactivated, to reduce spoilage risk?

RE: Bacterial spores are a lot much more resistant to dry warmth than to soaked heat. If there are dry lumps in the cocoa slurry, spores in them would not be absolutely hydrated, and could endure the UHT therapy. Hence, to make sure total hydration of the spores, the cocoa powder particles ought to be sufficiently hydrated before the warmth remedies.

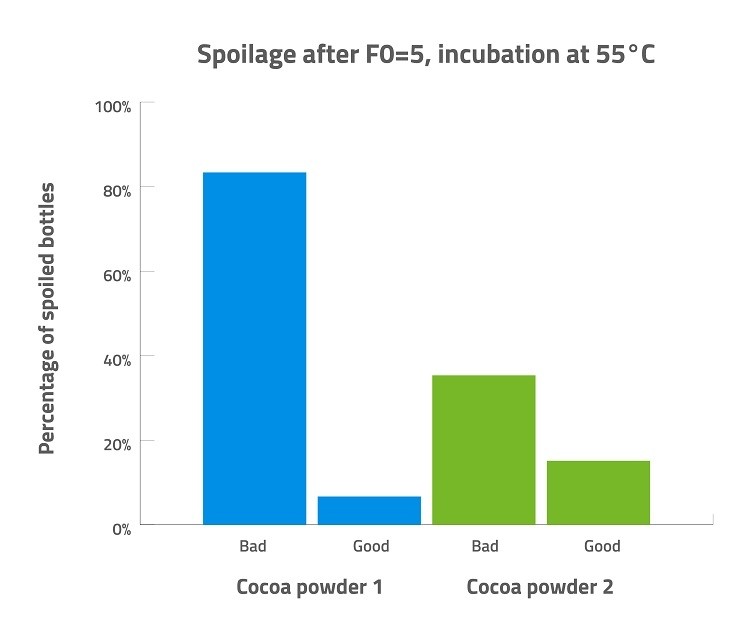

To improved recognize the partnership amongst hydration and spoilage, an industrial consortium built up of cocoa-creating corporations, cocoa-shopping for businesses, a know-how company and NIZO as an independent food items research partner, carried out a joint industrial investigate challenge. In a evidence-of-principle pilot experiment, two unique cocoa powders have been exposed to various hydration and thermal processing situations. These cocoa powders ended up specially selected for the functions of this review: one experienced a large focus of bacterial spores (this powder is not commercially obtainable), and one particular experienced minimal spore concentrations, but had been affiliated with a true spoilage incident.

Cocoa slurries of each sample were organized utilizing either a ‘bad’ (cold temperature, minimal time in the significant shear pump) or a ‘good’ (20 minutes of higher shear mixing at a greater heat) hydration process. The slurries ended up then used to make UHT-dealt with chocolate milk, which was saved in bottles in an incubator to allow for for germination and outgrowth of surviving spores.

The samples that went by means of the ‘good’ hydration process confirmed noticeably fewer spoilage than the samples working with the ‘bad’ approach. The benefits proved that the degree of hydration of cocoa throughout slurry preparation is essential in making sure the inactivation of bacterial spores through thermal processing, and that the most important parameter to achieve this powerful hydration is temperature (assuming ‘high shear’: really forceful mixing procedures working with large-pace impellers).

RF: What is the purpose of the industrial consortium, and what is the additional price of this joint strategy?

RE: The pre-competitive consortium is doing work together to assure constructive, constructive communication among cocoa suppliers, cocoa buyers and engineering providers, to align most effective methods, and to locate ways to cut down spore-connected spoilage danger in UHT beverages containing cocoa powder. It is very clear that no single issue is absolutely dependable for the unusual spoilage activities, so a holistic, multidisciplinary technique supported by scientific goal assessment is required.

The initially operate job of the consortium targeted on the difficulties of enumerating and identifying bacterial spores in cocoa powders. Responsible detection of the number of bacterial spores in cocoa powder applying normal plating strategies is complex by the antimicrobial influence, inadequate wettability and darkish color of cocoa.

The consortium made a science-primarily based reference strategy for figuring out spore concentrations in cocoa powders. The peer-reviewed paper provides a realistic and optimised approach, along with pro insights on how to interpret the benefits.

The second function venture focussed on the processing of cocoa for the production of UHT chocolate milk, particularly the diploma of hydration and its influence on spoilage by surviving spores right after thermal processing. The evidence-of-theory hydration pilot was component of this phase, and integrated the learnings and

formulated procedures from the whole task.

RF: What are the future techniques for the consortium?

RE: There are still really a couple of study steps needed to reach the consortium’s aims, which we will deal with in a stick to-up multidisciplinary investigate project. We will need to more optimise the methods for measuring hydration, together with defining the ideal options and the limitations for obtaining ideal dispersion and hydration of the cocoa powder. And we have to have to have an understanding of the impact and impression of homes this kind of as fats, starch, spore counts and spore kinds, and of processing options like temperature and time, cocoa focus, soaking, and so on. The consortium carries on to welcome new users to take part in the investigations.

The paper ‘Enumeration and Identification of Bacterial Spores in Cocoa Powder’ is accessible via Open up Obtain in The Journal of Food items Protection.

In our next article, we will glance at the problems associated in creating the subsequent technology of plant-centered drinks.

[ad_2]

Supply url